I built few more RC flasher boards. Few for friends and one more for another truck of mine. Same design as original but slightly different Arduino code.

Category Archives: RC Hobbies

New RC Car – Vaterra Kemora

A while ago a buddy of mine introduced me to a small 1:14 scale rally car. The Vaterra Kemora.

It’s decently well made, small RC car that comes with a brushless motor (4500KV) and even a Spektrum 2-channel radio. All for under $200. What really amazing about the price of the kit is that the individual replacement parts add up to much more than $200. It’s actually cheaper to buy another Kemora kit than order individual parts. This is just the perfect car for a small indoor track, like one we found locally not too long ago.

The biggest expense on my part was getting a few batteries for the car. While a lot of cheap options exist. I opted for the Traxxas #2820 2S Lipo packs. They fit the battery cavity well and provide healthy amount of capacity for nice long runs. Unlike a lot of cheaper batteries, they seem to keep their balance a lot better across cells and do not require balancing with every charge.

The car does have some minor issues though.

Tires

The local track uses silica covered painted concrete floor. Very harsh on the stock tires. The stockers went bald after only few batteries. Between few friends and I’ve tried several tire/wheel combinations that would last at the track and still give relatively good grip. I found the perfect combo! Duratrax Slicks (DTXC9722) and Wheels (DTXC9881). One of the cheapest and toughest combos we’ve tried yet. I have countless laps on these tires and a lot of contact between other cars and the walls and both wheels and tires are holding strong. Unlike a lot of slicks which are very plasticky, these tires are made from very sticky rubber. Even on the silica floor they provide just enough grip to go into corners fast but with just a blip of the throttle allow for easy drifts.

Other Issues

The motor runs very hot even on 2S batteries. We’ve seen upwards of 190F on the motor after a full battery run. I can’t imagine how this motor is to survive running on 3S. A motor heatsink is definitely recommended though due to the space constraints it might be difficult to find one that will fit. Currently running without the Chassis Cover to help keep the ESC and motor cooler. Will keep a lookout for a decent heatsink for this.

Another minor issues is the front axles have a tendency to pop out in minor collisions. The axles use a dog-bone design that takes a little bit of force to pop back in without having to take the tire off. It’s more annoying than anything, fortunately Vaterra offers upgraded axles that do not have this issue.

Lastly, the NiMh battery that I got with the truck was completely dead. It had an actual capacity of about 250mAh and cycling the pack repeatedly was not enough to bring it back to life. Not a big deal on my part as I was never planning to run on NiMH but again, something that Vaterra should address.

Issues aside this car is incredibly fun to race. And after countless laps and countless of collisions and rollovers, not a single part has been broken yet. It’s amazing actually as we’ve had some rather bad wrecks.

Update

After few hundred laps the stock body was getting pretty beat up (too many collisions). I got a new blank body and painted it. Added some nice lights by using 0.5W Ultra Bright 8mm LEDs for front and rear. Unlike my flasher project, these are just running lights.

I’m really digging this car. It’s a lot of fun to race for very little investment. And since it’s waterproof, it simply takes a quick hot shower in the sink at the end to clean it off. Hats of to Vaterra for this. Sounds like Traxxas has some real competition to their 1/16 Rally VXL.

RC Flasher Project

My RC Flasher Project is complete. I’ve done a write up of it here.

Traxxas Slash + 1W LEDs

A while ago I was browsing parts in a local hobby store and I came across an RPM part for my Traxxas Slash. It’s an offroad light bar (RPM #80922). The product is meant to be used with typical 3mm LED’s, in fact, RPM sells an LED kit that fits the canisters. Looking at the LEDs I knew the LEDs were for show only as the LEDs included don’t do much for illumination, typical 3mm LEDs produce between 1500 and 3000 mcd of light intensity with a rather narrow beam of light. Looks pretty, but that’s about it.

As soon as I saw this I knew I could take it to the next level. As I always say, if something is worth doing, it’s worth overdoing. So as soon as I got home I went on eBay and picked up a set of these puppies.

These are 1W Ultra Bright LEDs with built in heatsinks. These babies produce over 8000 mcd of light. Not only that, they have an extremely wide angle of view. These LEDs are blindingly bright, a perfect choice for some illumination for the truck.

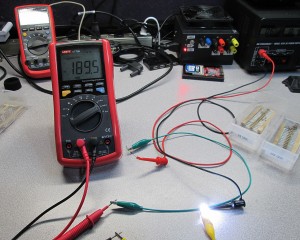

First step is to determine the best heat/brightness ratio. I did this by trying various values of resistors to get best brightness while maintaining heat at constant temperature. The LEDs in the canister will not be able to sink any heat. I used a thermal probe to get a reading on both the resistor and the LEDs heatsink. I ended up going with 22 ohm 1/4W resistors. After an hour under load the temperature was stable at 50C on the resistor and about 44C on the LED’s heatsink with ambient temperature of about 26C (toasty next to the servers).

I was having trouble finding some low gauge wire that I could use for the individual LEDs. The only thing I could find on spools was 24AWG which was still bit too thick for my liking. I stumbled across a roll of ribbon cable with what looked like 30AWG wire. It was perfect.

Soldering the LEDs was very quick and painless as the built in heatsink on the LED took care of protecting the LED from the heat from the soldering iron. The L#D canisters have a small hole in the back, the ribbon wire had no trouble passing through.

The next step is to solder the resistors inline. The best way I figured is to stagger the resistors so that when held together they don’t create a fat bundle.

After that it’s just a matter of going to town with heatshrink to isolate all connections

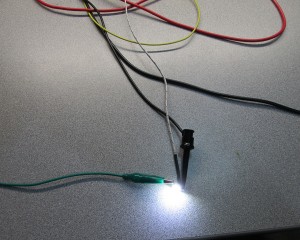

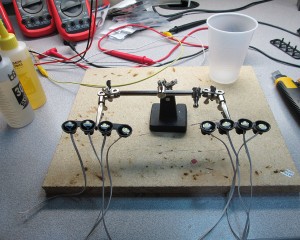

Before permanently affixing the LEDs in their respective canisters I needed to test the connections and make sure all LEDs light up.

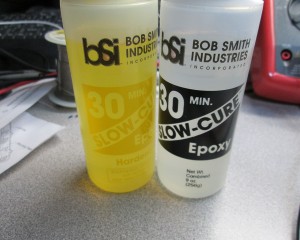

Once I confirmed that all LEDs are working properly, it was time to affix the LEDs to the canisters. I decided to use 30 minute Epoxy to give me plenty of time to align the LEDs properly.

What I missed though is that mixing a larger batch of epoxy causes a MUCH shorter curing time. In fact, the epoxy started to set just minutes after mixing the batch. I tried to work quickly applying the epoxy to each canister before the batch became unusable. The results were less than stellar. At least I still had time to align the LEDs but it was too late to try to remove some surplus.

The RPM kits came with lenses that can be used with the LED canisters. Unfortunately due to the size of the 1W LED, the lens can not be used in this configuration. Which I don’t think it’s a big deal, I can see the cheap plastic lens getting scratched and becoming opaque in very little time.

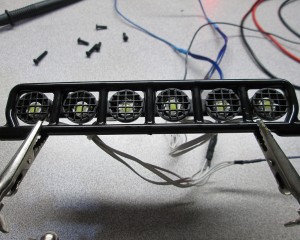

The grilles on for the canister fir perfectly though. Good thing too because it hides some of the ugly spillover epoxy inside the canisters. Mixed a much smaller batch this time so I had plenty of time to align the grilles.

Once the epoxy has cured it was time to attach the bar to the body and do final testing. The light bar actually fits very nicely on the truck.

Shortly after I did this build I decided to take another step and add the bumper lights. Plus a friend asked me to do a set for him too. Back onto eBay to pick up RPM #80982 and few extra LEDs.

The process was pretty much the same as building the top light bar.

Once all wiring was done. It was time again to test the new LED arrays. Once again, zero problems with soldering these things. Just 8 LEDs in an array gobbled up a full 1 AMP of current. Having 10 LEDs on the truck will definitely put the receiver connection at a strain.

Just like the top bar, the lenses were skipped due to LED size, but the grilles went on without issues.

Last step was to solder up some Futaba/JR connectors to the LEDs for easy connections. I’ve used some servo extensions to do the job. Just cut off the male connector and solder the female to the LED leads.

Time to do final mounting to the truck. Routed the wiring through the H frame.

The RPM kit fits perfectly in the bumper using existing screw holes. The LEDs are definitely bright. It huts my eyes just looking at them.

Some night shots. The camera really doesn’t do it justice. These LEDs are very, very bright.

Some quick snaps showing just how much illumination these things provide. Other than the little night light these were taken in near perfect darkness.

Traxxas 6814 Center Differential Rebuild

So a couple of friend and I decided to have a little bit of fun at a construction site near one of my buddies place. All was in great fun until my truck suddenly decided to stop.

http://www.youtube.com/watch?v=UbgVuVG1jcE

Turns out that the center slipper clutch was completely seized. This in turn caused the spur gear to be stripped (again).

When I got home, I dissembled the slipper clutch. The thing was completely filled with clay. It was in fact solid.

This is my first attempt at rebuilding the diff and since I don’t have the original manual for it, I’ll have to do without it.

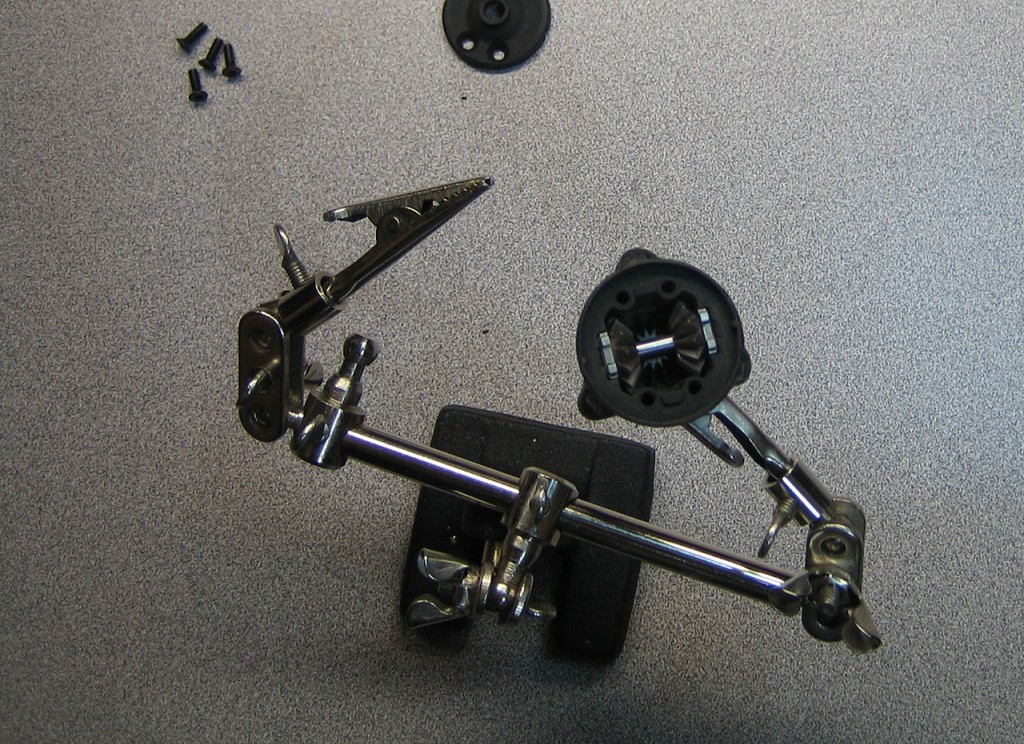

The diff disassembled. I was able to knock off some of the larger chunks of oil and clay. But the gear-set is still completely gunked up with the stuff.

I didn’t have a heavy duty degreaser that could remove the heavy silicone oil from the case. I ended up using nitro cleaner, brake cleaner and good ole toothbrush to get the parts clean. Took me over an hour to get all the parts completely free of debris. I’ll have to pick up some real engine degreaser to help me remove the stuff in the future.

The construction of the diff is actually pretty simple.

I used 50K weight silicone oil to fill the diff case. This stuff is pretty thick but I did saw that it was seeping a bit through the output shaft holes. Will have to keep an eye on it. Used a bit of blue threadlock to secure the set screws.

All done. Tomorrow I’ll tackle the rear diff. It looks smoked too.

Hitec Ultima X2

A few months ago I jumped back into the world of RC. This time though, I stayed with the relatively cheap hobby of RC Trucks and put the Heli hobby on the back-burner. Especially since the large (90 Size) helis no longer have that WOW factor seeing as everyone has an electric big box store heli now.

But I digress.

So, a while back I picked up a used Traxxas Slash 4×4 Platinum. Some guy was getting out of the hobby and decided to sell Everything in one shot. As part of the deal I got the Slash 4×4, Spektrum DX3R radio, a pretty kick-ass Stanley FatMax Toolbox and a countless number of replacement parts, receivers, tools and supplies. The only thing I needed was a few LiPo batteries to get me going.

Originally I was using a Bantam 501DX 5A Charger that I purchased years ago when LiPo’s first came to the RC world. Due to the limited charge speed of 5 amps there was a lot of down time between races while I waited for the batteries to charge.

I needed something better. I needed the ability to charge multiple batteries at once and the ability to charge high capacity batteries relatively quickly. When I started researching a decent LiPo charger, I quickly was overwhelmed by the sheer number of chargers available on the market. From simple plug-in and forget chargers to sophisticated chargers that can charge 6 batteries at once with programmable features and other do-dads.

Due to the fact that I was out of the hobby for many years, I decided to stick to a company name that I knew. Enter the Hitec Ultima X2. Hitec has been in the RC industry for as long as I remember. So at least I knew I was getting a decent product .

The Hitec Ultima X2 is a dual DC charger that can charge batteries up to 10A per port.

The charge comes with most common connectors for batteries, but unfortunately it does not come with Traxxas connectors. Also included are two LiPo balancer breakout boards and aligator clamp adapters for the banana plug power connectors.

The unit supports external temperature sensors for charging batteries. Comes with a USB interface to hook up to a computer and use with Hitec’s battery charge monitoring software. And a USB Charge jack which surprisingly only offers 1A of current capacity. This makes it pretty much useless for most devices nowadays that require at least 1.4A.

The display/programming interface is identical to the Bantam Charger I’ve had for years, leading me to believe that the processor for the charger is made by the same company and it’s been cranking out the same chip for years. I guess the old adage still goes, if It ain’t broke, don’t fix it.

Overall the charger is a great buy. The ability to fast charge multiple batteries simultaneously is a great feature. At 20A maximum draw one does have to be careful to not completely drain the car battery if using it to power the charger. I recommend leaving the engine running while charging or else you might need a jump.

I might look to buy a small Honda generator in the future if I find that I’m heavily into this hobby. But then again, if I’m getting into it as I got into RC Helis and Airplanes, this could mean big $$ in the future.